Your are here: Home > Products > Gantry Crane > >20 ton Gantry Crane > 150 ton Gantry Crane

ABB motor Driven 150 ton Gantry Crane is designed and made in accorance with the duty calssification.

- reasonable price

- ABB motor driven

- safe and reliable travelling, long life.

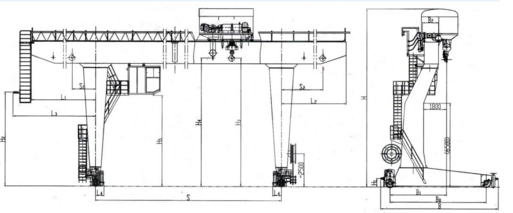

The 150 ton gantry crane is a heavy duty double girder gantry crane. double girder gantry crane with electric winch trolley is composed of gantry, crane crab, trolley traveling mechanism, cab and electric control system, the gantry is box-shape structure, the track is at the side of each girder and the leg is divided into type A and type U according to user’s requirements.

- ABB motor driven

- safe and reliable travelling, long life.

- Overload Limiter, Limit Switch (Lifting and Traveling), Interlock protection device, Buffer, Rail clear plate, Protective cover, Bus Bar preventer plate, Anti-collision device, Light alarm devices Main isolating switch, Emergency stop system, Motor overload protection

-Equipped with rainproof devices for lifting mechanism, electrical control box.

| Capacity | 5~500 tons |

| Lift height | 3~60m |

| Span | 3~35m |

| Work duty | M3~M8 |

| Protection class | IP55 |

| Working temperature | -20~+40℃ |

Customer can obtain consultation and communicate with us through network platform, telephone, E-mail and MSN and etc. We provide technical matters as well as product knowledge and information concerned with products. We can provide premium, effective and reliable solutions and quotations according to customers' requirements and budgets. We also provide customer-case visiting to understand utilizations of our products at site. We warmly welcome customers to visit our factory prior to placing an order.

We have always designed products stringently according to contracts and customers' requirements. We have always manufactured stringently according to ISO 9001 quality management system. We have always strictly inspected each component of each product to ensure product quality.

After-sale service department consists of well-trained technical personnel and installation engineers. Our professional technical personnel can provide installation guidance, device debugging and operation training at site or through remote operation. Routine maintenance information is accessible.